Drying Technology of Cassava Residue

This process is used for drying all kinds of high humidity dregs and residues with viscous materials.

These residues are fibrous substances. They combine with water more strongly. Although they are dehydrated by extrusion, the moisture content of the extruded wet cassava residue is still 65-70%. In addition, there are a small amount of starch and protein in the wet residue, which is sticky and easy to agglomerate. It is difficult to dry with general drying equipment.

In view of the above characteristics, the drying temperature it needs should start at high temperature (about 450 C), then pass through medium and low temperature (300-160 C), and have a longer drying time. At the same time, it needs to loosen the aggregates while drying. At the same time, it needs to drain the evaporated water vapor in time, otherwise it will affect the heat transfer effect and not easy to dry.

The fuels used for drying can be coal, methane, wood, orange pole, etc. If the fuels which produce more dust in use, high temperature dust collector should be added to reduce the dust in high temperature gas to ensure product quality.

This production line is carefully designed in accordance with this principle. Through production practice, it has been proved that the effect is good and the economic benefit is high. Generally, the investment can be recovered in about 6 months.

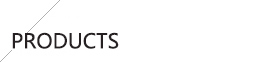

technical parameter:

This process is used for drying all kinds of high humidity dregs and residues with viscous materials.

These residues are fibrous substances. They combine with water more strongly. Although they are dehydrated by extrusion, the moisture content of the extruded wet cassava residue is still 65-70%. In addition, there are a small amount of starch and protein in the wet residue, which is sticky and easy to agglomerate. It is difficult to dry with general drying equipment.

In view of the above characteristics, the drying temperature it needs should start at high temperature (about 450 C), then pass through medium and low temperature (300-160 C), and have a longer drying time. At the same time, it needs to loosen the aggregates while drying. At the same time, it needs to drain the evaporated water vapor in time, otherwise it will affect the heat transfer effect and not easy to dry.

The fuels used for drying can be coal, methane, wood, orange pole, etc. If the fuels which produce more dust in use, high temperature dust collector should be added to reduce the dust in high temperature gas to ensure product quality.

This production line is carefully designed in accordance with this principle. Through production practice, it has been proved that the effect is good and the economic benefit is high. Generally, the investment can be recovered in about 6 months.

technical parameter:

Evaporating 1T of water requires about 600-700,000 Kcal of heat

Cost and profit accounting based on data provided by Vietnamese customers:

1. Drying cassava residue by hot air requires 600,000 Kcal of heat to evaporate 1 ton of water.

2. The calorific value of biogas is 4700 Kcal/m to 4800 Kcal/m, so the total consumption of biogas is about 5.3 million kcal/4750 kcal = 1120 m; and the biogas price of 1 m is about 0.7 yuan, so drying 4 tons of cassava residue requires about 0.7 *1120 = 784 yuan, while the fuel of cassava residue per ton is 784/4 = 196 yuan.

3. Artificial Fu-120 yuan *7 (7 persons/shift) = 840 yuan/shift, that is 105 yuan/hour, totaling 1369 yuan/hour (the price of raw material wet residue is not included);

4. The cost of finished slag per ton is 1369/4=342.25 yuan; the selling price of finished slag per ton is 850-900 yuan; therefore, the net profit of finished slag per ton is 850 yuan-342.25=507.75 yuan; the total profit of finished slag is 507.75 48744 yuan per day, about 96 tons per day.

Flow chart of cassava residue drying process:

Cost and profit accounting based on data provided by Vietnamese customers:

1. Drying cassava residue by hot air requires 600,000 Kcal of heat to evaporate 1 ton of water.

2. The calorific value of biogas is 4700 Kcal/m to 4800 Kcal/m, so the total consumption of biogas is about 5.3 million kcal/4750 kcal = 1120 m; and the biogas price of 1 m is about 0.7 yuan, so drying 4 tons of cassava residue requires about 0.7 *1120 = 784 yuan, while the fuel of cassava residue per ton is 784/4 = 196 yuan.

3. Artificial Fu-120 yuan *7 (7 persons/shift) = 840 yuan/shift, that is 105 yuan/hour, totaling 1369 yuan/hour (the price of raw material wet residue is not included);

4. The cost of finished slag per ton is 1369/4=342.25 yuan; the selling price of finished slag per ton is 850-900 yuan; therefore, the net profit of finished slag per ton is 850 yuan-342.25=507.75 yuan; the total profit of finished slag is 507.75 48744 yuan per day, about 96 tons per day.

Flow chart of cassava residue drying process:

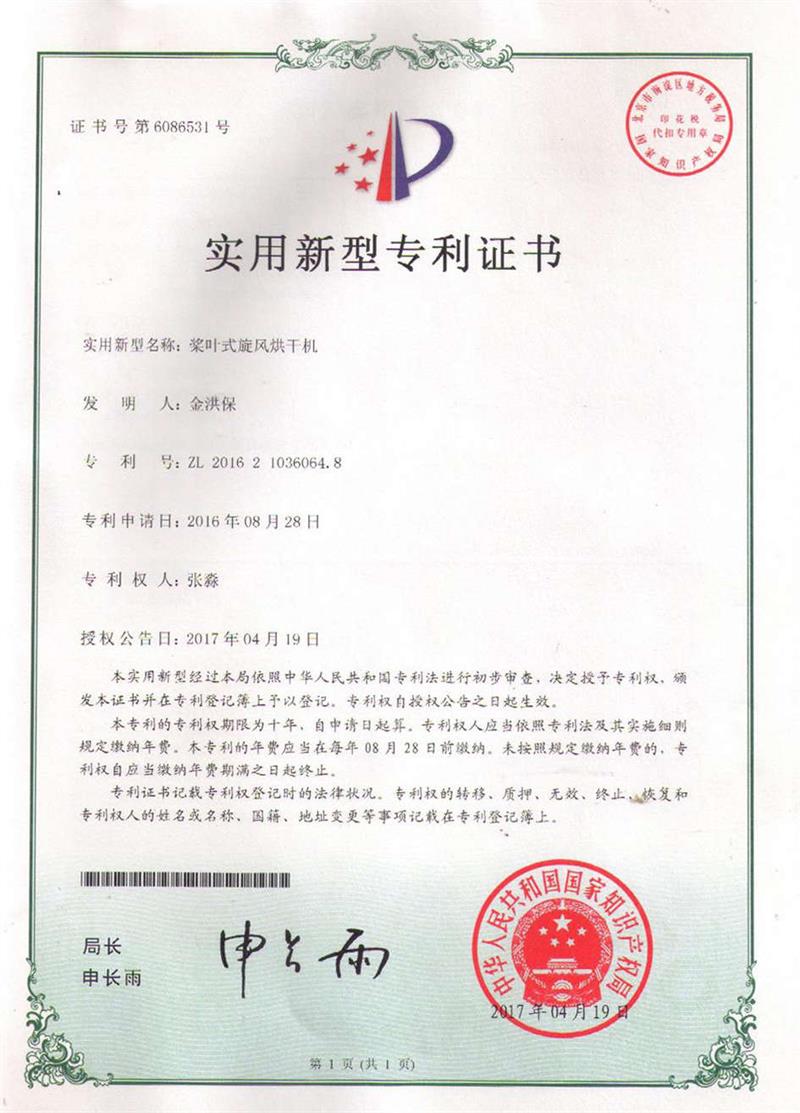

Patent Certificate

越南怡发淀粉厂(3.6吨木薯渣烘干生产线)