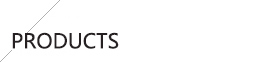

ZXG series dryer absorbs the advantages of similar products abroad and improves to a certain extent. The main advantages of the machine are low heat consumption, high efficiency and energy saving, wide range of drying materials, large capacity of treatment, large amount of water evaporation and drying of high moisture materials, large drying elasticity (can adjust drying time according to different material properties and moisture requirements), continuous operation (i.e., high degree of automation), and intermittent operation (suitable for special processes). The machine has fewer auxiliary equipments and compact layout with small area. It can be placed in a single-storey factory building, so the cost of civil engineering can be greatly saved. In addition, the machine has little process wear, easy installation and low maintenance cost.

Drying operation data:

Continuous operation and intermittent operation for special materials. There are few auxiliary equipments, small area occupied by cluster mainframe, large processing capacity, energy saving and low consumption.

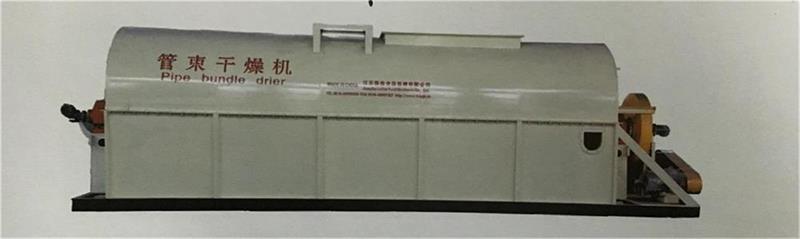

Heat transfer mode: non-contact heat conduction and radiation.

Heating medium: saturated steam.

It is an effective means and reasonable technological arrangement to reduce the total energy consumption of drying when wet material is put into the machine after dehydration treatment.

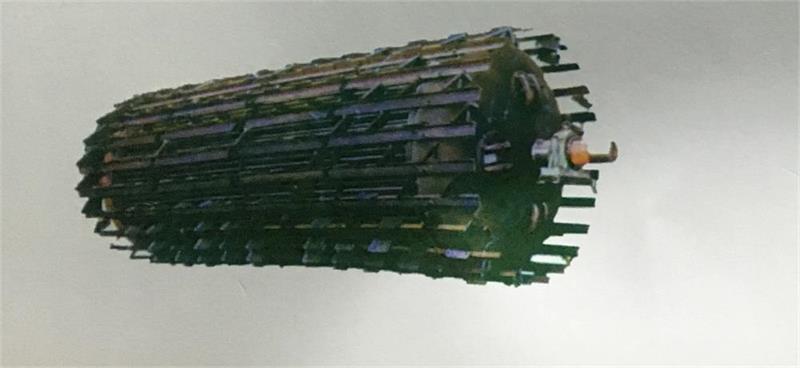

After the wet material enters the mixing screw and mixes with a suitable amount of dry material, the wet material can be effectively avoided sticking to the wall and the drying operation conditions can be improved by screwing the feed into the machine.

Suitable materials for operation should be dry and loose materials, which can be powder, granular, flaky, or other monomer materials.

The flow direction of steam in the bundle is opposite to the flow direction of material outside the bundle: the low-speed rotating bundle is discharged by continuously turning over animal material with a follower shovel and pushing the material in the direction of the outlet at the steam inlet end.

Examples of application areas

Corn starch industry: drying corn germ, fiber, protein powder and corn feed (fiber + gluten + pre-concentrated corn soaking solution + syrup, etc.)

Extraction industry: processing soybeans, sunflower seeds, rapeseed and other oilseed fruits

The basic composition of the unit: main engine; steam intake system; condensate water system; dry matter recovery system; material transfer system; heat exchanger (heat exchanger is an optional component)

Reference drying process data of several commonly processed materials