Summary

MQG series airflow dryer uses high-speed hot air to suspend the dried material, and the pulse airflow generated by the change of pipe diameter makes the material roll continuously, and dries the material in the process of airflow conveying.

MQG series airflow dryer has been successfully used in the final drying of corn and potato starch, protein powder, flake and some heat sensitive materials.

main features

(1) Using piecewise variable diameter pulse tube, the fluctuation of airflow velocity can be changed, and the heat transfer coefficient can be greatly improved.

Energy is saved greatly in drying operation.

(2) The material drying process only takes about one second, and the material temperature does not exceed 50 C.

(3) The device operates under negative pressure, and the working environment is clean, pollution-free and efficient.

(4) The energy consumption and steam consumption of the whole machine are lower than those of other drying equipment, which is an energy-saving product.

(5) The utility model has the advantages of simple structure, convenient operation and use, small occupation area and low investment.

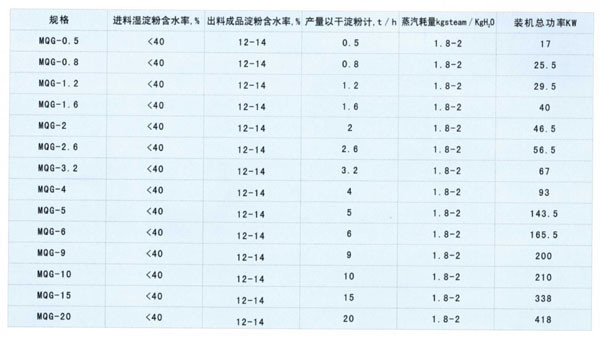

Main specifications and technical parameters

MQG series airflow dryer uses high-speed hot air to suspend the dried material, and the pulse airflow generated by the change of pipe diameter makes the material roll continuously, and dries the material in the process of airflow conveying.

MQG series airflow dryer has been successfully used in the final drying of corn and potato starch, protein powder, flake and some heat sensitive materials.

main features

(1) Using piecewise variable diameter pulse tube, the fluctuation of airflow velocity can be changed, and the heat transfer coefficient can be greatly improved.

Energy is saved greatly in drying operation.

(2) The material drying process only takes about one second, and the material temperature does not exceed 50 C.

(3) The device operates under negative pressure, and the working environment is clean, pollution-free and efficient.

(4) The energy consumption and steam consumption of the whole machine are lower than those of other drying equipment, which is an energy-saving product.

(5) The utility model has the advantages of simple structure, convenient operation and use, small occupation area and low investment.

Main specifications and technical parameters

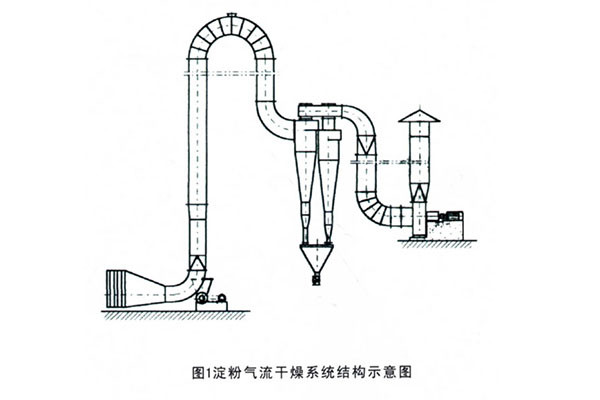

Main structure and working principle

1. Overall structure

The structure of corn starch airflow drying system is as follows.

The system is mainly composed of screw feeder, hoist, air heater, air filter, cyclone separator and centrifugal fan.

1. Air inlet 2. Air filter 3. Air heater 4. Condensate outlet 5. Steam inlet 6. Lifter 7. Spiral feeder 8. Wet starch inlet 9. Starch finished product outlet 10. Shut-off 11. Fan 12. Dry air duct 13. Cyclone separator 14. Exhaust gas outlet

2. Working Principle

The airflow drying system uses high-speed hot air to disperse and suspend water-bearing materials, and dries them in the process of airflow conveying. Because of the high velocity of air flow, the suspension of material particles in the air flow, the great heat transfer surface between gas and solid, the high heat transfer coefficient and the short drying time (most materials only need a few seconds to dry), it is especially suitable for the drying of heat sensitive materials.

In the drying process, the filtered clean cold air is heated by air heater and mixed with the wet starch which is sent from the feeder to the air duct through the hoister. The dry starch is instantly dried. The dried starch is discharged by cyclone separator and shutter for packaging, and the exhaust gas is discharged into the atmosphere through the fan.

The machine can be operated by automatic control and manual control. When automatic control is adopted, the humidity of exhaust gas is automatically measured by the moisture controller, and the signal is fed back to the speed regulating motor of the feeder to control the feeding amount, so as to ensure the water content of the product.

1. Overall structure

The structure of corn starch airflow drying system is as follows.

The system is mainly composed of screw feeder, hoist, air heater, air filter, cyclone separator and centrifugal fan.

1. Air inlet 2. Air filter 3. Air heater 4. Condensate outlet 5. Steam inlet 6. Lifter 7. Spiral feeder 8. Wet starch inlet 9. Starch finished product outlet 10. Shut-off 11. Fan 12. Dry air duct 13. Cyclone separator 14. Exhaust gas outlet

2. Working Principle

The airflow drying system uses high-speed hot air to disperse and suspend water-bearing materials, and dries them in the process of airflow conveying. Because of the high velocity of air flow, the suspension of material particles in the air flow, the great heat transfer surface between gas and solid, the high heat transfer coefficient and the short drying time (most materials only need a few seconds to dry), it is especially suitable for the drying of heat sensitive materials.

In the drying process, the filtered clean cold air is heated by air heater and mixed with the wet starch which is sent from the feeder to the air duct through the hoister. The dry starch is instantly dried. The dried starch is discharged by cyclone separator and shutter for packaging, and the exhaust gas is discharged into the atmosphere through the fan.

The machine can be operated by automatic control and manual control. When automatic control is adopted, the humidity of exhaust gas is automatically measured by the moisture controller, and the signal is fed back to the speed regulating motor of the feeder to control the feeding amount, so as to ensure the water content of the product.